There are three important aspects that should be considered when determine the best threading method; the thread, the component and machine parameters.

The thread

After analyzing the thread features, look at the component:

The thread

- External or internal thread

- Through or blind hole

- Thread profile (metric, UN etc.)

- Thread pitch

- Right or left-hand thread

- No. of thread starts

- Tolerance (profile, position)

After analyzing the thread features, look at the component:

- Can the component be fixed securely?

- Chip evacuation issues? Does the material have good chip breaking qualities?

- Component batch size. Mass production of threads may justify an optimized tool to maximize productivity

- Single or multi-start threads

- Component shape

- Machine parameters

- Stability, power and torque requirements, especially for larger diameters

- Component clamping

- Tool position (upside-down can facilitate chip evacuation)

- Thread cycle should be easy to program

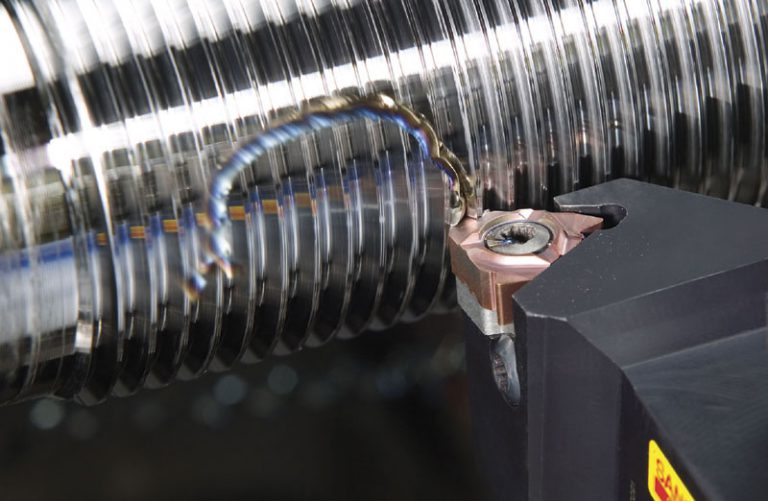

- Cutting fluid and coolant